1. Why should I use a genuine grease cartridge?

2. Comparison with non-genuine grease

1. Development history of Genuine grease

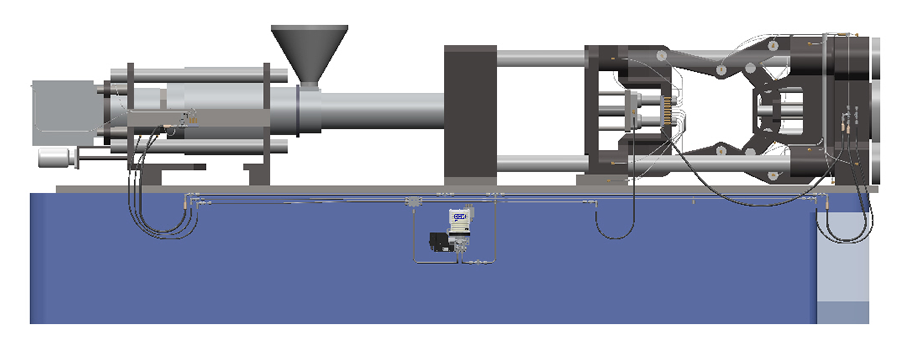

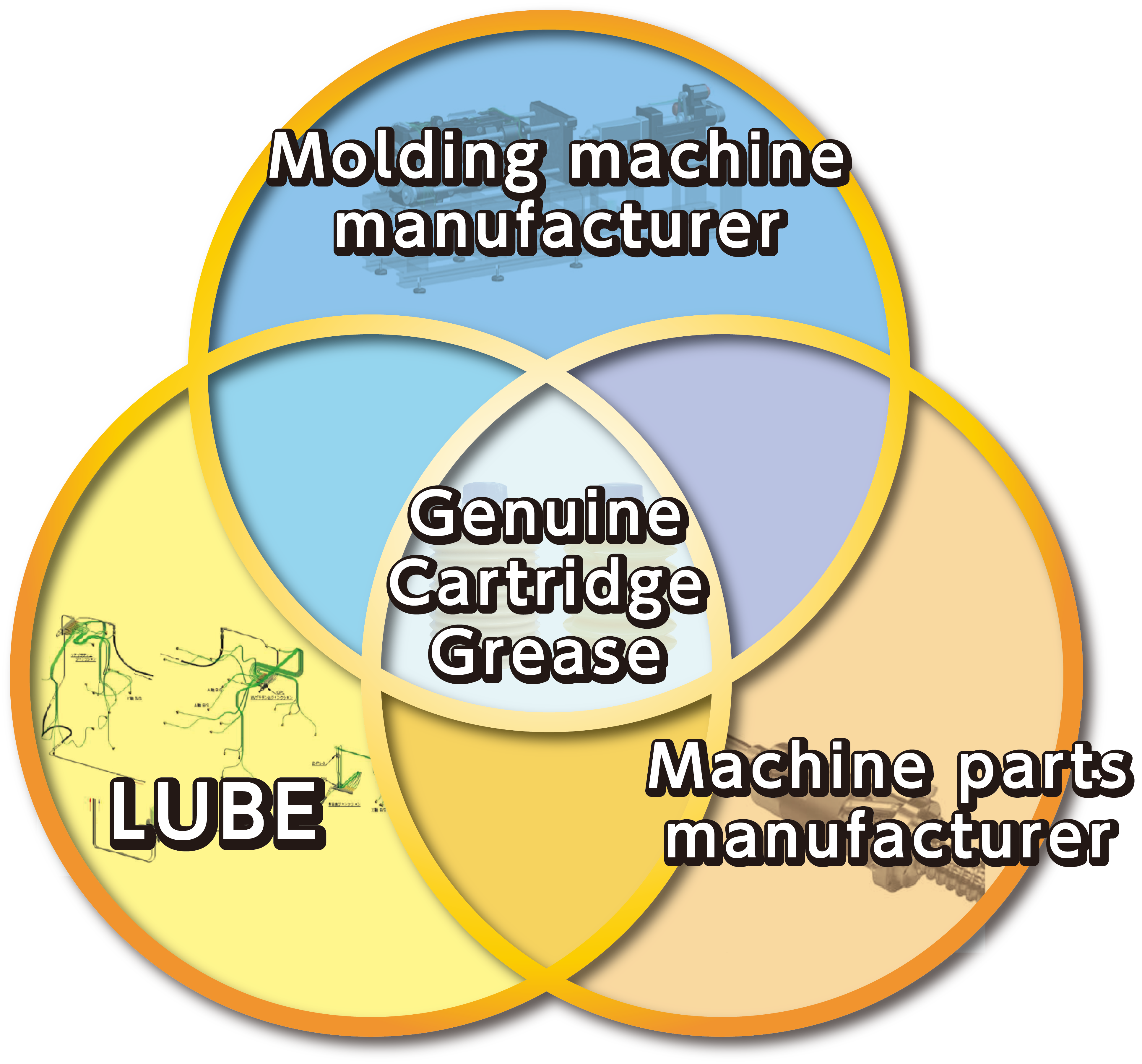

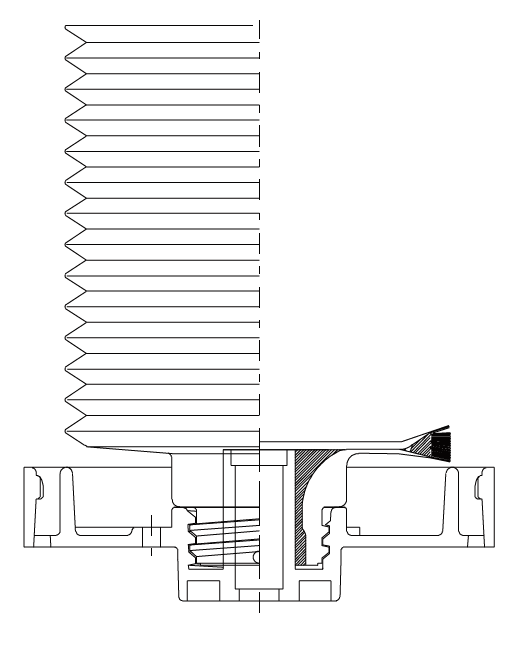

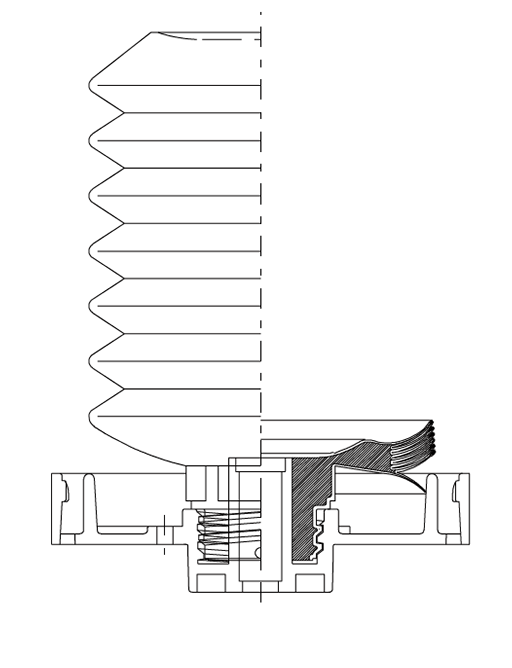

In the injection molding machine industry, Japanese molding machine manufacturers adopted and manufactured electric drive molding machines with high precision, stable and stable molding and excellent energy saving from 17 years ago. As the internal structure of the molding machine has largely changed to a structure mainly based on "ball screws for high load", a grease agent for high load that is appropriate for it has become essential, so manufacturers of molding machines and component parts manufacturers, etc. At Lube, we developed a high-load cartridge grease that can be fed by a centralized lubrication system.

Reliable lubrication is performed based on a system evaluation test using a combination of genuine grease and grease system.

Molding machine manufacturer

- Ideal lubrication condition

- Ideal lubricant

- maintenance

- Proper amount of lubrication

LUBE

- Evaluation and proposal of optimal system for various environment and conditions

- Verification of grease solidification mechanism

- Pursuit performance evaluation such as inflow and adhesion of lubricant

2.Comparison with non-genuine grease

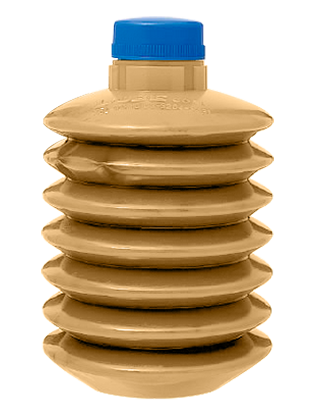

2-1. About Lube Original Grease (Comparison of Container Shape and Remaining Rate)

| Genuine cartridge | Non genuine cartridge | |

|

|

|

|

|

|

| Used |

|

|

| Grease remaining amount | 28ml | 75ml |

| Remaining rate | 4.0% | 10.5% |

2-2.About Lube original grease (performance evaluation)

Load bearing capacity

High-speed four-ball load bearing performance test results(N)

| Genuine grease | Non-genuine grease | |||

| High speed four ball type Load bearing capacity N |

LNL | ASTM D2596 | 1236 | 1236 |

| WL | 3923 | 3089 | ||

| LWI | 650 | 589 | ||

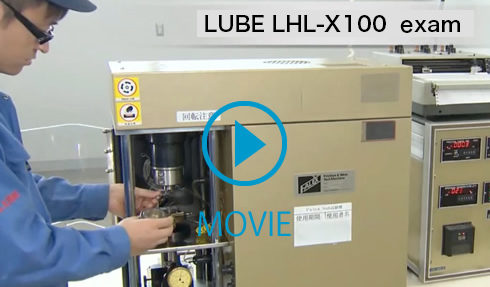

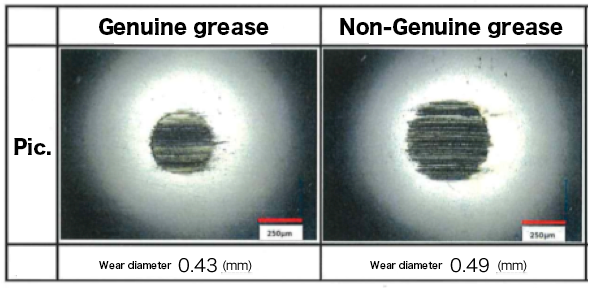

Wear resistance performance

Four-ball wear test results(75℃,40Kg,1200rpm,1h)

Copyright(C) 2014 LUBE Corporation All rights reserved.