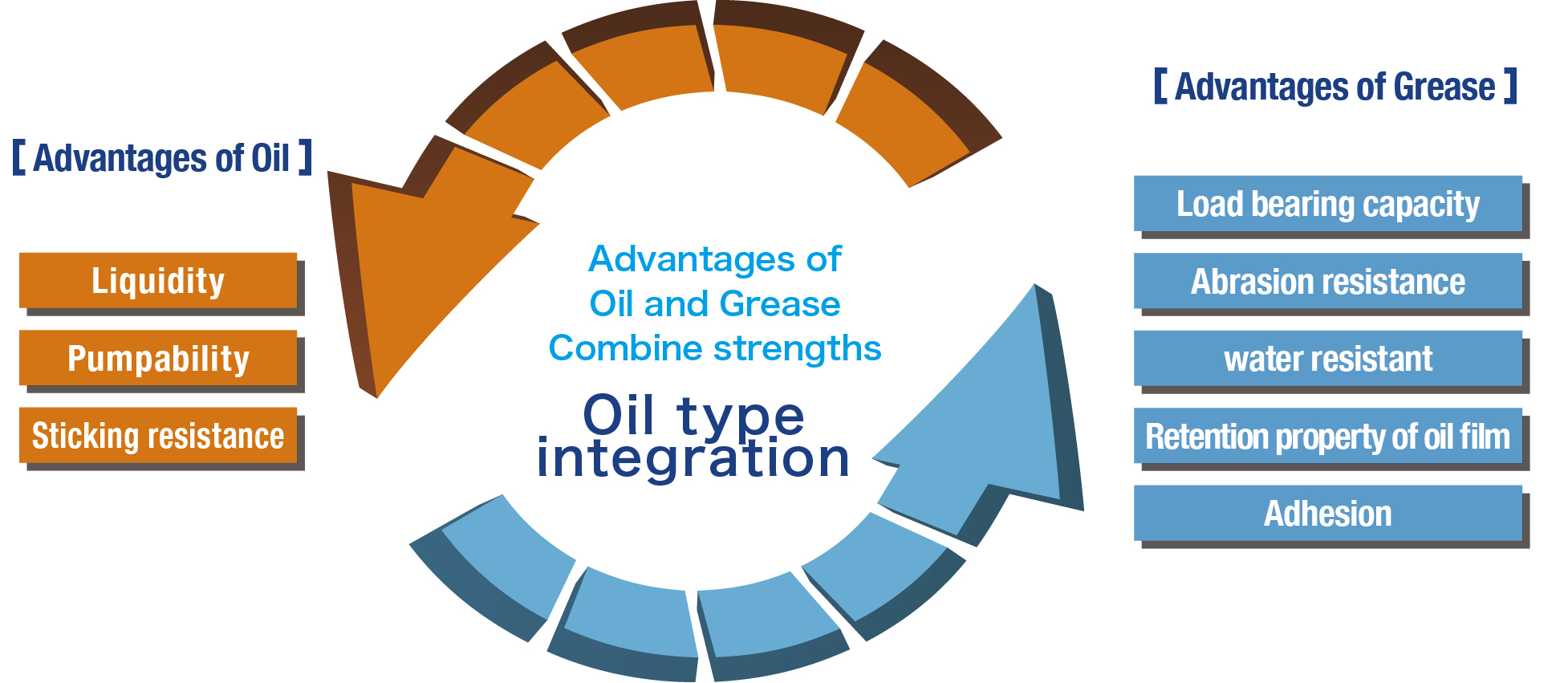

The next generation of lubricant that contribute to the environment and human

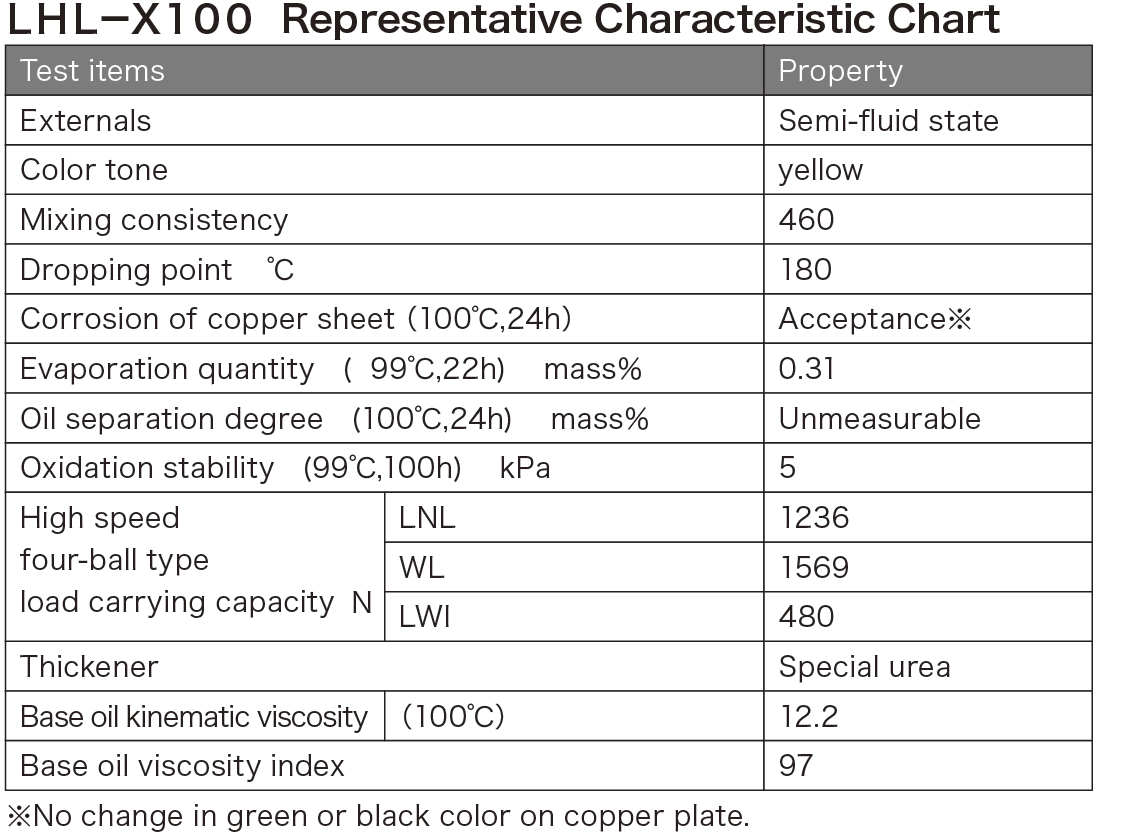

● prevent the linear guide of galling or abnormal wear of high load.

● suppress the occurrence of rust prevention and excellent corrosion resistance to emulsification due to moisture contamination.

● forms a strong oil film on the rolling surface of the linear motion guide.

● because it is possible to timely and appropriate amount of lubrication, ideal lubricating effect can be obtained.

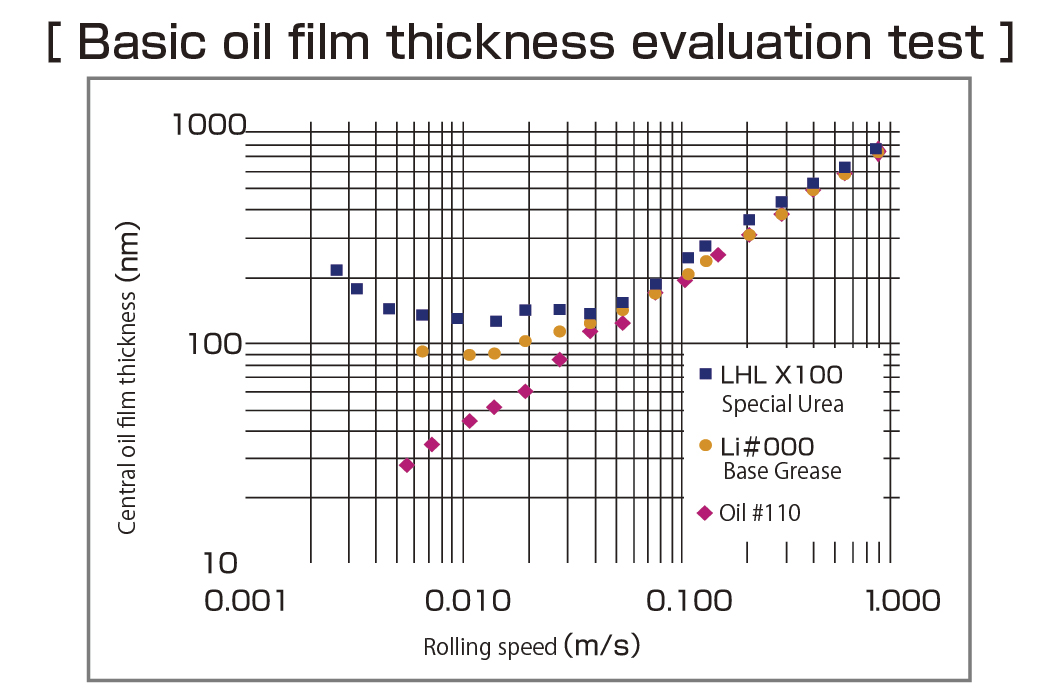

LHL-X100 special urea grease is thicker in the low-speed range than Li soap grease

As a result of investigation by focusing on the oil film thickness as the base of lubricating performance, rolling is (close to zero) becomes zero area it was found that thinnest of oil film. In addition, in a comparison of oil and grease, but more of grease oil film is thick, very generally than lithium grease, which is also used to prevent the oil film becomes thicker oil film is more of this special urea grease Among them I can do it.

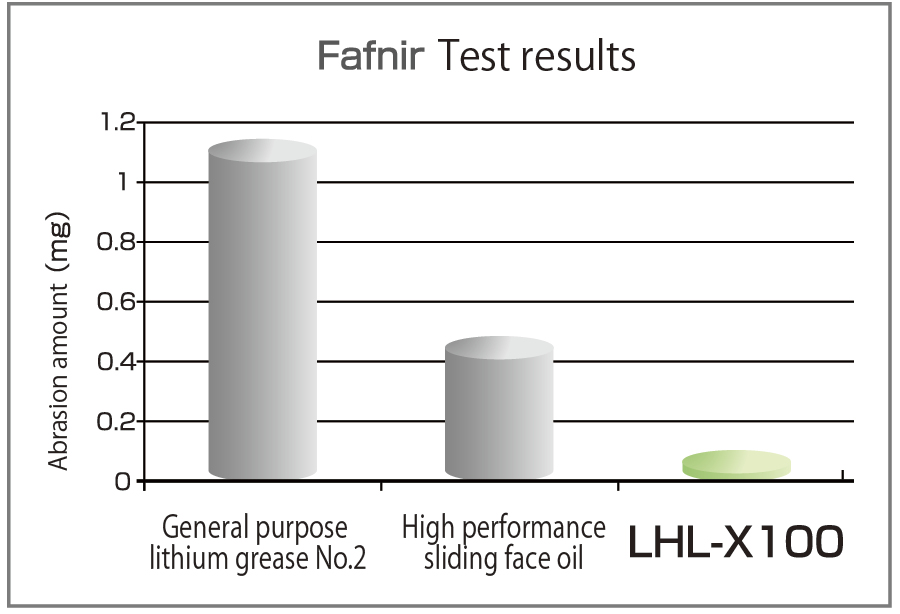

[Of wear by fretting] LHL-X100 fretting resistance

● test method

· Fafnir test (in accordance with ASTM D4170)

● test conditions

· Bearing: ANDREW W 5/8 (2 sets used)

· Load: 2450N (surface pressure: 1861MPa)

- Swing angle: 12 ° (average rolling speed: 0.065m / s)

· Swing cycle: 25Hz

Temperature: 25 ℃

· Grease quantity: bearing 1 set per 1.0 ± 0.05g

Measuring the amount of wear: the race mass decrease of per set bearing.

(Down the total mass of the test bearing race / 2)

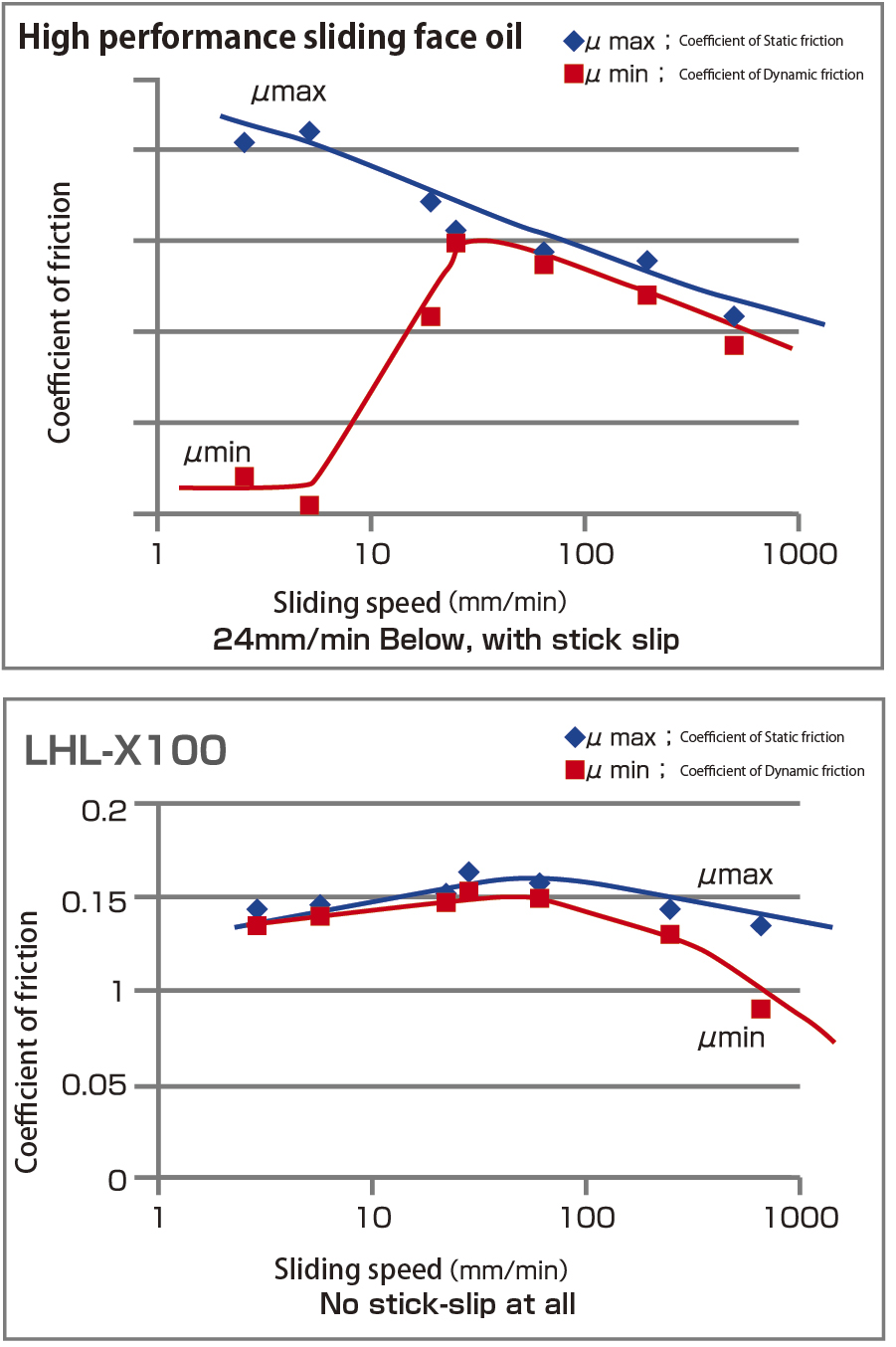

LHL-X100 is stick slip did not occur in all of the test speed. This is, compared with the higher sliding surface oils, the additives and special urea structure even at low speeds, firmly lubricating film on sliding metal surfaces is formed, believed that preventing metal contact you.

● test method

1. Tester: Bowden testing machine

2. Test conditions Material: steel - steel temperature: room temperature

Load: 4kgf speed: 3,6,24,30,60,240,600mm / min